The regenerative high-temperature air combustion method (HTAC) is a new combustion technology with great energy-saving and environmental protection functions.

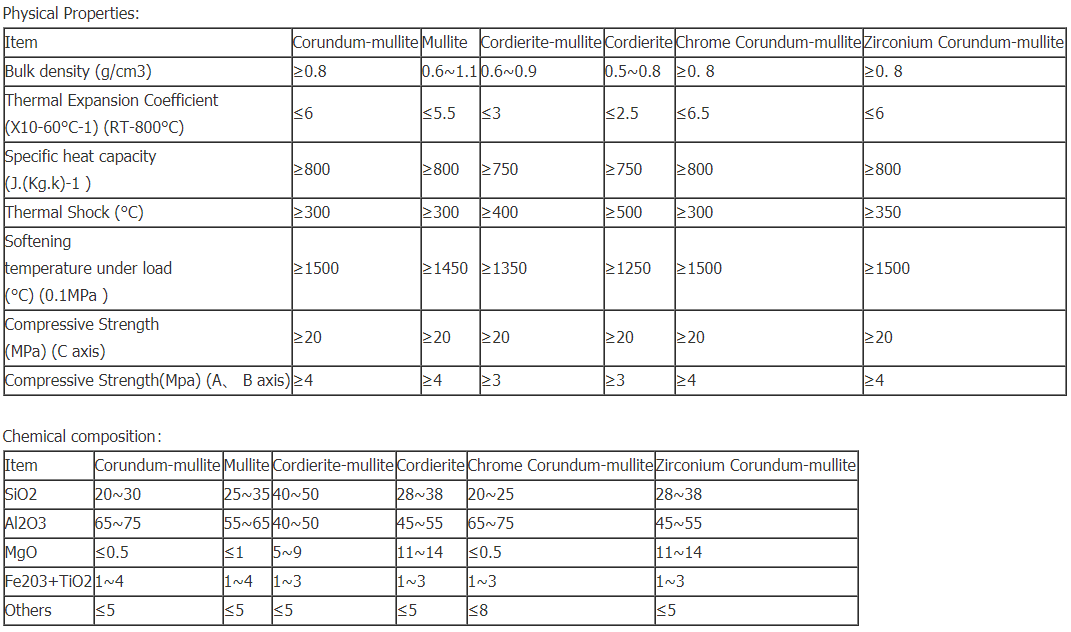

- Al2O3: ≥65.8%;

- Fe2O3: 0.60-0.68%;

- Bulk Density: 0.8-1.0g/cm³;

- Classification Temperature: 1400-1600℃;

- Cold Crushing Strength: 5.5MPa;

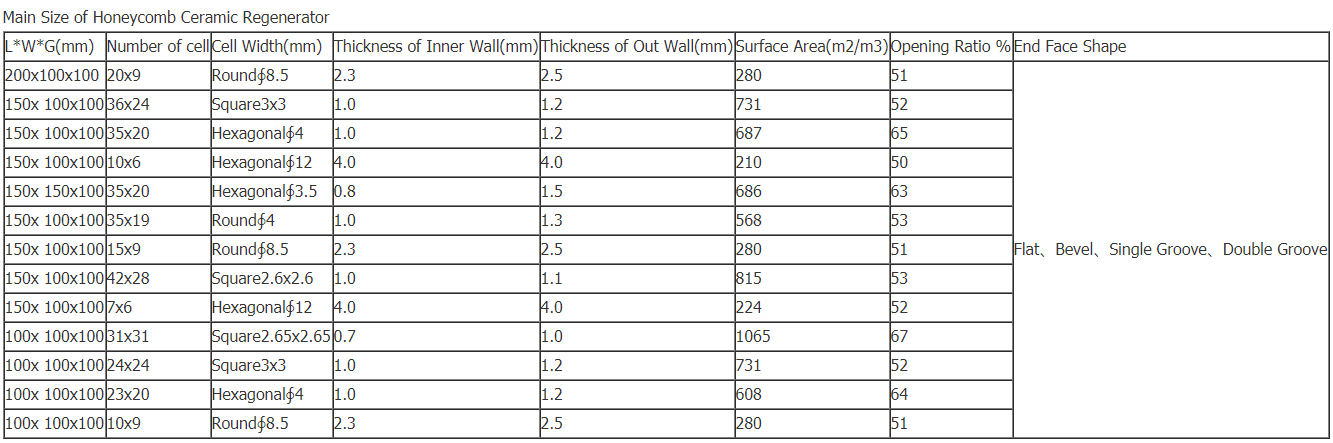

- Size: 100*100*100mm (standard) and others;

- Delivery: 15-30 working days;

Our Whatsapp: +86 15936223891

Our Email: [email protected]

Inquiry Now

Please fill in the following table, and we will reply you as soon as possible!

The regenerative high-temperature air combustion method (HTAC) is a new combustion technology with great energy-saving and environmental protection functions. The honeycomb ceramic regenerator,also known as ceramic regenerator and ceramic honeycomb, is a key components of regenerative burner,widely used in steel, machinery, building materials, petrochemical, non-ferrous metal smelting and other industries,such as push- type heating furnace,step-type heating furnace, heat treatment furnace,ladle/ tundish roaster, forging furnace, melting furnace,soaking furnace, radiant tube burner, hood furnace,blast furnace hot blast stove, oil and gas boiler; various ceramic kiln in building materials industry,various glass kiln; various tubular heating furnace,cracking furnace and other in petrochemical industry furnaces.

The technology is to make two regenerative alternating heat absorption exotherms through the reversing device,to recover the heat of the flue gas to the maximum limit, and then to heat the combustion air and gas in the furnace to above 1000 C,it can achieve stable ignition and efficient combustion even the low calorific value of the inferior combustion, saving fuel up to 40-70 °C. The output will be increased by more than 15 °C, the oxidation loss of the steel embryo will be reduced by more than 40%,the NO2 emission will be less than 100 pm,and the exhaust gas temperature will be lower than 150"C, which greatly reduces the greenhouse effect of the earth' s atmosphere. If most of industrial furnaces in the country adopt HTAC technology, its economic and social benefits are immeasurable,which will greatly alleviate the shortage of energy and improve the living environment of human beings. Since its launch in the market, it has achieved good results and is favored by the steel smelting industry.

Ronghua Refractory is Your Ideal Expert

Ronghua Refractory’s vermiculite insulation bricks are multifunctional. And they have a long lifespan. When you choose our products, you are not just investing in mullite insulation bricks, but also in quality assurance and peace of mind service. Ronghua Refractory provide you with the most suitable vermiculite insulation bricks and insulation solutions. Please send us your detailed requirements now.